A University of Missouri researcher has developed a “virtual wall” which could stop the spread of oil and help build an invisible barrier to contain oil spills. The following is a University of Missouri News Release, dated December 2, 2013:

The outer shell of a droplet of oil on a surface has a thin skin which allows it to hold its shape like a small dome; this shell is referred to as the liquid’s surface tension. Now, researchers at the University of Missouri have developed a technique to form a virtual wall for oily liquids that will help confine them to a certain area, aiding researchers who are studying these complex molecules. This development will have future implications in the guided delivery of oil and effective blockage of oil spreading.

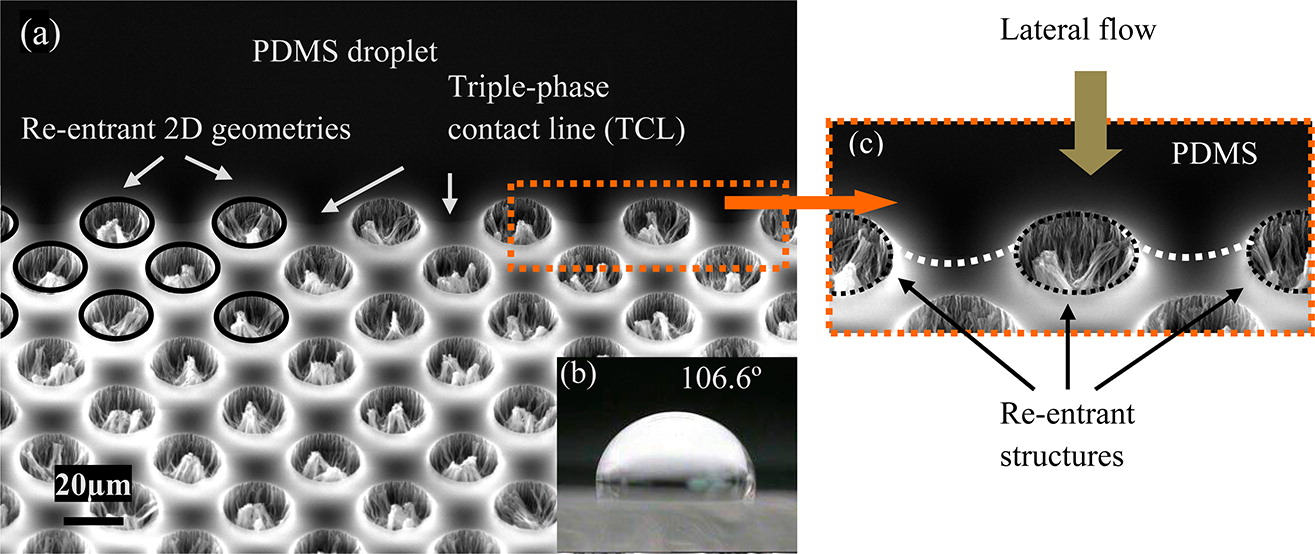

“Our work is based on micro/nanoelectromechanical systems, or M/NEMS, which can be thought of as miniaturized electrical or mechanical structures that allow researchers to conduct their work on the micro/nanoscopic level,” said Jae Kwon, associate professor of electrical and computer engineering in the College of Engineering at MU. “Oil-based materials or low-surface tension liquids, which can wet any surface and spread very easily, pose challenges to researchers who need to control those tiny oil droplets on microdevices.”

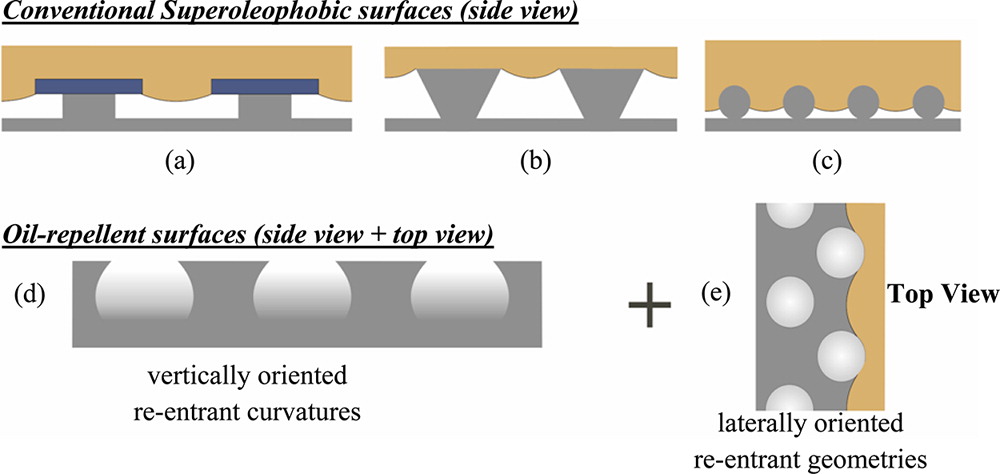

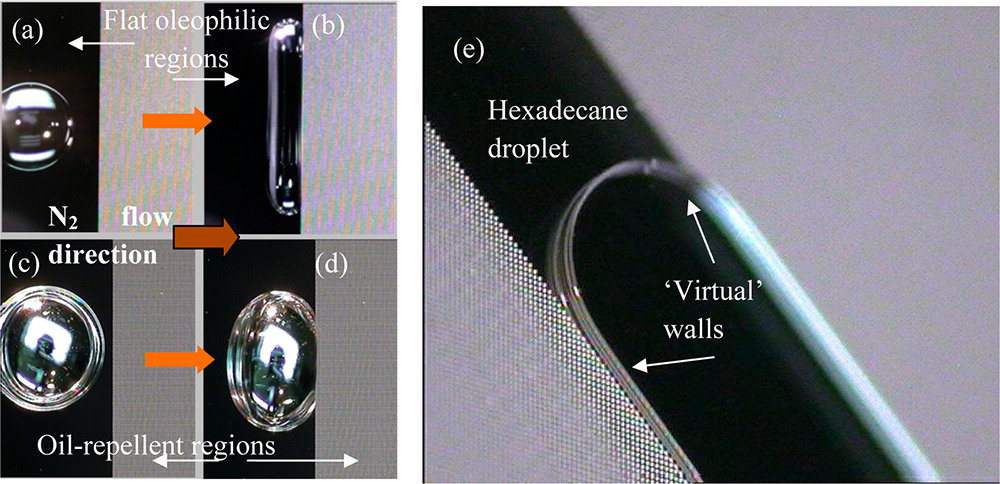

Oil-based compounds are referred to as low-surface tension liquids because they tend to spread on the surface of a researcher’s microscope slides or microarrays where the liquids are placed. Additionally, as can be seen from oil spills in the Gulf of Mexico, oil can stick and easily spread out on any surface. Using specially designed oil-repellent surfaces, Kwon and his group demonstrated invisible “virtual walls” which block spreading of low-surface tension liquids at the boundary line with microscopic features already created in the device.

“Our newly developed surface helped keep oil, which is normally unmanageable, in predetermined pathways making it controllable. We feel that oil-repellant surfaces can be widely utilized for many industrial applications, and virtual walls for low-surface tension liquids also have immense potential for many lab-on-a-chip devices which are crucial to current and future research techniques.”

Kwon suggests that in the future, oil-repellent virtual walls may be used to control the transport of oil without spillage. The research, “Virtual walls based on oil-repellant surfaces for low-surface tension liquids,” was conducted by Kwon and Riberet Almeida, a graduate student in the College of Engineering, and was published in the journal Langmuir, a peer-reviewed scientific journal published by the American Chemical Society.