If you happen to own a boat and would like to take to try it out on Lake Cachuma, prepare yourself for some hassle before launching it. The County of Santa Barbara prohibits access to Cachuma Lake County Park for any California-registered boat and trailer that violates any of the following requirements:

- Owners of boats and trailers that pass the visual inspection must show current California vessel registration and sign an affidavit attesting that: 1) the boat and trailer have not been in waters infested by quagga or zebra mussels within the previous 30 days; and 2) that no live bait other than commercially purchased worms and night crawlers are in their possession.

- All boats and trailers entering Cachuma Lake County Park will be inspected and must be clean and dry. Boat hulls must be free of foreign matter. All bilges, live wells, bait tanks, integral coolers, or any other compartment within the boat must be clean and dry, including ballasts.

- Boats and trailers that pass the visual inspection will be required to be treated with a heated power wash prior to being cleared for launch in Cachuma Lake.

- The following vessels are subject to mandatory 14-day quarantine: all boats that are longer than 24 feet, all out-of-state boats, all boats with ballast tanks, all boats registered in any counties in California that contain infected waters, and all boats that have been in quagga or zebra mussel-infected waters within the previous 30 days.

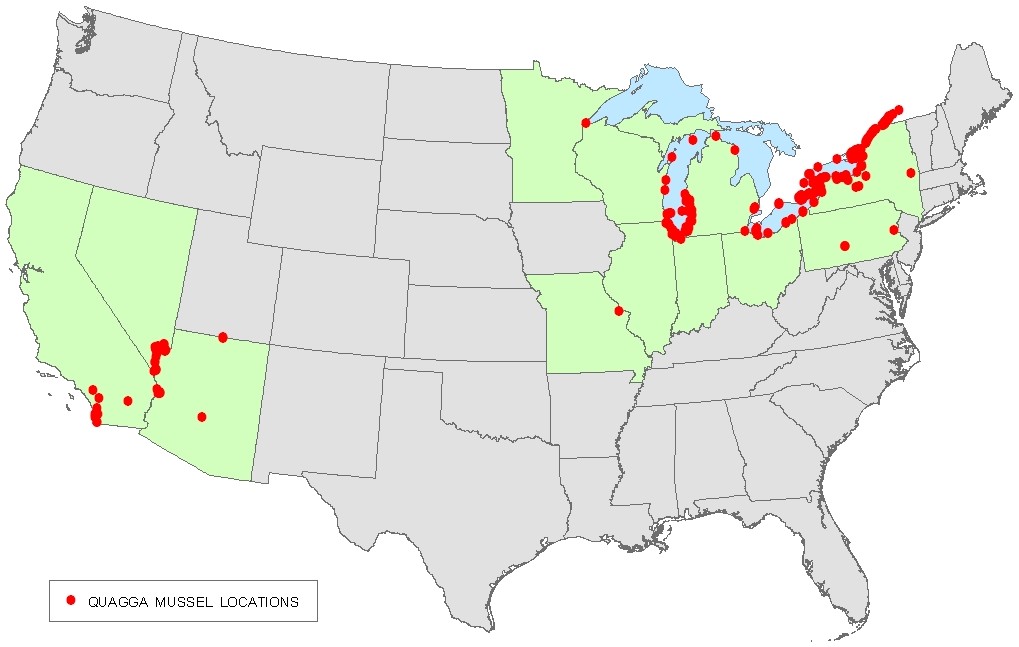

Why the big fuss over little mussels? Zebra mussels (Dreissena polymorpha) and quagga mussels (Dreissena rostriformis bugensis), natives of Eastern Europe, are tiny, invasive freshwater mussels which have plagued European and U.S. waterways for the last two decades, altering food chains, destroying native mussel populations, and clogging water pipes, thereby damaging boats, power plants, reservoirs, and industrial facilities. Lacking effective natural predators, these mussels have spread rapidly and are now found in 21 states. In 2007, the U.S. Geological Survey estimated that the cost of controlling zebra mussels in the Great Lakes region alone would reach $5 billion annually, and Great Britain’s Anglian Water Authority alone says it currently spends £500,000 a year on combating the mollusk.

“The need for controlling zebra mussels has spawned a multi-million dollar industry. Removal of established zebra mussels is usually a temporary solution. Treatments must be repeated periodically as recolonization occurs unless Dreissena is completely removed from the entire body of water, which is relatively impossible in most cases. Methods of controlling zebra mussels include: chemical controls, biological controls, oxygen deprivation, thermal treatment, exposure and dessication, radiation, manual scraping, high-pressure jetting, mechanical filtration, and removable substrates” (source). These control measures are complicated by the fact that a single, mature female mussel can produce up to one million eggs per year, that adult zebra mussels can survive out of water for several days or weeks if the temperature is low and humidity is high, that they rapidly adapt to extreme environmental conditions, and that they can sense poisons in the water and simply close their shells for up to three weeks until the threat has dissipated.

“Thankfully, a Cambridge-based company called Biobullets has come up with a much easier – and cheaper – means of removing them. A method that owes much to the ancient Greeks and their Trojan horse. ‘We ‘sugar-coat’ a toxin to trick the mussels into eating it,’ says Biobullets co-founder and Cambridge University marine biology lecturer David Aldridge. ‘And when I say sugar-coat, what we actually do is cover tiny particles in a tasty vegetable fat. The zebra mussels then eat the Biobullets, building up a concentration of the toxic without realizing it until it kills them, and they fall away.’ The toxin in question, potassium chloride, is safe to use in the water supply system as anything that is not eaten by the zebra mussels degrades in less than three hours. (See the 2006 Environmental Science and Technology article on the subject here.)

Founded back in 2000 by Mr Aldridge and fellow Cambridge lecturer Geoff Moggridge, Biobullets has been financially supported by the government’s Technology Strategy Board (TSB), including a £557,000 grant in 2009. The UK’s national innovation agency, one of TSB’s key roles is helping to connect university research projects with private companies. It was in this regard that TSB assisted Biobullets in finding a business that could manufacture the company’s product on a large scale. The manufacturer in question is Bristol-based food industry business Tastetech, which employs about 40 people. A food company may not immediately seem appropriate, but Tastetech actually turned out to be a perfect fit. This is because Biobullets needed a manufacturer which could ensure that the toxins in the granules were released in a controlled manner, and Tastetech’s expertise in the food industry is the slow release of flavorings, such as in chewing gum. ‘Obviously we had to be careful because we are a food manufacturer,’ says Tastetech’s process development manager Peter Sargent. ‘So we built a completely separate new plant. We’ve essentially spent the last decade improving and refining the product, and are ready to go to full production, potentially 3,000 tonnes per year.’ As trials with UK water companies have proved successful, Dr. Aldridge says he plans to launch the product commercially later this year” (source).

Article by Bill Norrington